Faceware Announces New Facial Motion Capture Hardware

/0 Comments/in New Hardware, News/by Travis ReinkeLeica Geosystems and Autodesk Announce BLK360 $16k 3D Laser Scanner

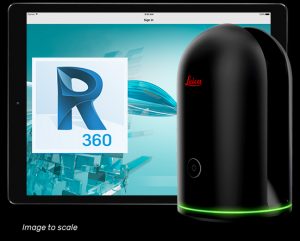

/0 Comments/in 3D Laser Scanning, LiDAR, New Hardware, New Technology, News, Point Cloud/by Travis ReinkeLeica Geosystems Announces Complete Imaging Solution: Leica BLK360 Imaging Laser Scanner and Autodesk ReCap 360 Pro App

Las Vegas, November 16th, 2016, Leica Geosystems announced the BLK360, a revolutionary miniaturized black 3D imaging laser scanner. The product was revealed at Autodesk University 2016 and will be bundled with Autodesk’s ReCap 360 Pro and the new ReCap 360 Pro app for iPad. Both companies will demonstrate the product for the duration of the conference at the ReCap booth #2033 and the Leica Geosystems booth #1537.

The BLK360 captures the world around you with full-color panoramic images overlaid on a high accuracy point cloud. The one-button Leica BLK360 is not only the smallest and lightest of its kind, but also offers a simple user experience. Anyone who can operate an iPad can now capture the world around them with high resolution 3D panoramic images.

The Leica BLK360 defines a new category: the imaging laser scanner. It is so small and light that it fits in a typical messenger bag and can be carried almost anywhere. It features a 60 meter measurement range for full dome scans. A complete full-dome laser scan, 3D panoramic image capture and transfer to the iPad Pro takes only 3 minutes.

“When Autodesk first introduced ReCap, it was for one purpose: the democratization of reality capture,” said Aaron Morris, who oversees reality solutions at Autodesk. “We saw the tremendous power of this technology for the AEC industry, but realized that the cost and portability of scanners combined with difficult-to-use data was limiting the adoption of reality capture. Autodesk’s collaboration with Leica Geosystems helps solve these issues by giving just about anyone access to the amazing advantages of reality data.”

“As the leader in the spatial measurement arena, we recognized the gap between Leica Geosystems’ scientific-grade 3D laser scanners and emerging camera and handheld technologies, and set out to bring reality capture to everyone,” said Dr. Burkhard Boeckem, CTO of Hexagon Geosystems. “By combining and miniaturizing technologies available within Hexagon, the BLK360 defines a new category: the Imaging Laser Scanner. It is significantly smaller and lighter (1 kg) than any comparable device on the market. As we developed the ultimate sensor, we worked with Autodesk to create new software and ultimately achieved the next milestone in 3D reality capture. Together with Autodesk’s ReCap 360 Pro, the Leica BLK360 empowers every AEC professional to realize the benefits gained by incorporating high resolution 360° imagery and 3D laser scan data in their daily work.”

BLK360 & Autodesk ReCap 360 Pro Bundle will be available to order in March 2017. The anticipated bundle suggested retail price is $15,990/€15,000, which includes: BLK360 Scanner, Case, Battery, Charger and an annual subscription to ReCap 360 Pro. For customers who want to secure their spot in line to receive the first batch of BLK360 laser scanners, Autodesk and Leica Geosystems are offering a special limited promotion for a discounted three-year ReCap 360 Pro subscription with a voucher giving priority access to buy the BLK360. Go to this link to learn more.

Leica Geosystems – when it has to be right

Revolutionizing the world of measurement and survey for nearly 200 years, Leica Geosystems creates complete solutions for professionals across the planet. Known for premium products and innovative solution development, professionals in a diverse mix of industries, such as aerospace and defense, safety and security, construction, and manufacturing, trust Leica Geosystems for all their geospatial needs. With precise and accurate instruments, sophisticated software, and trusted services, Leica Geosystems delivers value every day to those shaping the future of our world.

Leica Geosystems is part of Hexagon (Nasdaq Stockholm: HEXA B; hexagon.com), a leading global provider of information technologies that drive quality and productivity improvements across geospatial and industrial enterprise applications.

Autodesk, the Autodesk logo, Autodesk ReCap 360, and Autodesk ReCap 360 Pro are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and/or other countries. All other brand names, product names or trademarks belong to their respective holders. Autodesk reserves the right to alter product and services offerings, and specifications and pricing at any time without notice, and is not responsible for typographical or graphical errors that may appear in this document.

FARO® Launches the Focus S Laser Scanner with IP54 Rating and In-Field Compensation for Construction BIM-CIM and Public Safety Forensics Professionals

/0 Comments/in 3D Laser Scanning, New Hardware/by Travis ReinkeLAKE MARY, Fla., Oct. 10, 2016 /PRNewswire/ — FARO® (NASDAQ: FARO), the world’s most trusted source for 3D measurement and imaging solutions for factory metrology, product design, construction BIM/CIM, public safety forensics and 3D solutions and services applications, announces the release of the all-new FARO FocusS Laser Scanner.

The FocusS is the newest member of FARO’s popular Focus Laser Scanner product line and is available in both 150m and 350m ranges. Designed for construction BIM-CIM and public safety forensics applications, this new line of laser scanners brings together several customer-centric features such as an increased measurement range, Ingress Protection (IP) Rating of 54 for use in high particulate and wet weather conditions, an accessory bay for custom add-on devices and a built-in field compensation routine for ensuring system accuracy at all times.

“Establishing a new benchmark against the highly successful Focus3D models of the past 5 years, FARO’s Research & Development Team continues to set a high standard for laser scanners. Equipped with highly advanced features in an ergonomic and durable design, the FocusS 150 and 350 are packed with today’s most innovative features to maximize efficiencies for laser scanning professionals,” stated Joe Arezone, Chief Commercial Officer of FARO.

With a sealed design, the FocusS laser scanner is certified to a Class 54 IP rating, featuring safeguards against intrusions such as dirt, dust, fog and rain as well as other outdoor elements which can occur in extreme scanning conditions.

To ensure confidence in accuracy, the on-site compensation feature enables users to verify the accuracy of the FocusS before each project on-site. Users can correct deviations caused during transport, carrier mishandling or incidental contact automatically on-site and a comprehensive accuracy document can be provided for each scan project.

With the integrated accessory bay, additional accessories can easily be connected to the scanner. Customers and third party developers can augment their scanning capabilities by utilizing this accessory port for future technological customization.

“Customers who have field tested our new laser scanners are truly excited about the overall capabilities, quality and affordability of the units which are unique to the market,” stated Andreas Gerster, Vice President of Construction BIM-CIM & Product Design at FARO.

The FocusS Laser Scanners are available for immediate shipment. More information on FARO’s FocusS Laser Scanners is available at: www.faro.com/focus

This press release contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995 that are subject to risks and uncertainties, such as statements about demand for and customer acceptance of FARO’s products, and FARO’s product development and product launches. Statements that are not historical facts or that describe the Company’s plans, objectives, projections, expectations, assumptions, strategies, or goals are forward-looking statements. In addition, words such as “is,” “will” and similar expressions or discussions of FARO’s plans or other intentions identify forward-looking statements. Forward-looking statements are not guarantees of future performance and are subject to various known and unknown risks, uncertainties, and other factors that may cause actual results, performances, or achievements to differ materially from future results, performances, or achievements expressed or implied by such forward-looking statements. Consequently, undue reliance should not be placed on these forward-looking statements.

Factors that could cause actual results to differ materially from what is expressed or forecasted in such forward-looking statements include, but are not limited to:

- development by others of new or improved products, processes or technologies that make the Company’s products less competitive or obsolete;

- the Company’s inability to maintain its technological advantage by developing new products and enhancing its existing products;

- declines or other adverse changes, or lack of improvement, in industries that the Company serves or the domestic and international economies in the regions of the world where the Company operates and other general economic, business, and financial conditions; and

- other risks detailed in Part I, Item 1A. Risk Factors in the Company’s Annual Report on Form 10-K for the year ended December 31, 2015.

Forward-looking statements in this release represent the Company’s judgment as of the date of this release. The Company undertakes no obligation to update publicly any forward-looking statements, whether as a result of new information, future events, or otherwise, unless otherwise required by law.

About FARO

FARO is the world’s most trusted source for 3D measurement, imaging and realization technology. The Company develops and markets computer-aided measurement and imaging devices and software. Technology from FARO permits high-precision 3D measurement, imaging and comparison of parts and complex structures within production and quality assurance processes. The devices are used for inspecting components and assemblies, rapid prototyping, documenting large volume spaces or structures in 3D, surveying and construction, as well as for investigation and reconstruction of accident sites or crime scenes.

FARO’s global headquarters are located in Lake Mary, Florida. The Company also has a technology center and manufacturing facility consisting of approximately 90,400 square feet located in Exton, Pennsylvania containing research and development, manufacturing and service operations of its FARO Laser Tracker™ and FARO Cobalt Array Imager product lines. The Company’s European regional headquarters is located in Stuttgart, Germany and its Asia Pacific regional headquarters is located in Singapore. FARO has other offices in the United States, Canada, Mexico, Brazil, Germany, the United Kingdom, France, Spain, Italy, Poland, Turkey, the Netherlands, Switzerland, India, China, Malaysia, Vietnam, Thailand, South Korea, and Japan.

More information is available at http://www.faro.com

Photo – http://photos.prnewswire.com/prnh/20161009/426696

Photo – http://photos.prnewswire.com/prnh/20161009/426697

Logo – http://photos.prnewswire.com/prnh/20110415/MM84316LOGO

SOURCE FARO Technologies, Inc.

Related Links

Velodyne LiDAR Announces Puck Hi-Res™ LiDAR Sensor

/0 Comments/in LiDAR, Mobile Scanning, New Hardware, New Technology/by Travis ReinkeVelodyne LiDAR Announces Puck Hi-Res™ LiDAR Sensor, Offering Higher Resolution to Identify Objects at Greater Distances

Industry-leading, real-time LiDAR sensor impacts autonomous vehicle, 3D mapping and surveillance industries with significantly higher resolution of 3D images

MORGAN HILL, Calif.–(BUSINESS WIRE)–Velodyne LiDAR Inc., the recognized global leader in Light, Detection and Ranging (LiDAR) technology, today unveiled its new Puck Hi-Res™ sensor, a version of the company’s groundbreaking LiDAR Puck that provides higher resolution in captured 3D images, which allows objects to be identified at greater distances. Puck Hi-Res is the third new LiDAR sensor released by the company this year, joining the standard VLP-16 Puck™ and the Puck LITE™.

“Not only does the Puck Hi-Res provide greater detail in longer ranges, but it retains all the functions of the original VLP-16 Puck that shook up these industries when it was introduced in September 2014.”

“Introducing a high-resolution LiDAR solution is essential to advancing any industry that leverages the capture of 3D images, from autonomous navigation to mapping to surveillance,” said Mike Jellen, President and COO, Velodyne LiDAR. “The Puck Hi-Res sensor will provide the most detailed 3D views possible from LiDAR, enabling widespread adoption of this technology while increasing safety and reliability.”

Expanding on Velodyne LiDAR’s groundbreaking VLP-16 Puck, a 16-channel, real-time 3D LiDAR sensor that weighs just 830 grams, Puck Hi-Res is used in applications that require greater resolution in the captured 3D image. Puck Hi-Res retains the VLP-16 Puck’s 360° horizontal field-of-view (FoV) and 100-meter range, but delivers a 20° vertical FoV for a tighter channel distribution – 1.33° between channels instead of 2.00° – to deliver greater details in the 3D image at longer ranges. This will enable the host system to not only detect, but also better discern, objects at these greater distances.

“Building on the VLP-16 Puck and the Puck LITE, the Puck Hi-Res was an intuitive next step for us, as the evolution of the various industries that rely on LiDAR showed the need for higher resolution 3D imaging,” said Wayne Seto, product line manager, Velodyne LiDAR. “Not only does the Puck Hi-Res provide greater detail in longer ranges, but it retains all the functions of the original VLP-16 Puck that shook up these industries when it was introduced in September 2014.”

“The 3D imaging market is expected to grow from $5.71B in 2015 to $15.15B in 2020, led by the development of autonomous shuttles for large campuses, airports, and basically anywhere there’s a need to safely move people and cargo,” said Dr. Rajender Thusu, Industry Principal for Sensors & Instruments, Frost & Sullivan. “We expect Velodyne LiDAR’s line of sensors to play a key role in this surge in autonomous vehicle development, as the company leads the way in partnerships with key industry drivers, along with the fact that sensors like the new Puck Hi-Res are substantially more sophisticated than competitive offerings and increasingly accessible to all industry players.”

Velodyne LiDAR is now accepting orders for Puck Hi-Res, with a lead-time of approximately eight weeks.

About Velodyne LiDAR

Founded in 1983 by David S. Hall, Velodyne Acoustics Inc. first disrupted the premium audio market through Hall’s patented invention of virtually distortion-less, servo-driven subwoofers. Hall subsequently leveraged his knowledge of robotics and 3D visualization systems to invent ground breaking sensor technology for self-driving cars and 3D mapping, introducing the HDL-64 Solid-State Hybrid LiDAR sensor in 2005. Since then, Velodyne LiDAR has emerged as the leading supplier of solid-state hybrid LiDAR sensor technology used in a variety of commercial applications including advanced automotive safety systems, autonomous driving, 3D mobile mapping, 3D aerial mapping and security. The compact, lightweight HDL-32E sensor is available for applications including UAVs, while the VLP-16 LiDAR Puck is a 16-channel LiDAR sensor that is both substantially smaller and dramatically less expensive than previous generation sensors. To read more about the technology, including white papers, visit http://www.velodynelidar.com.

Contacts

Velodyne LiDAR

Laurel Nissen

lnissen@velodyne.com

or

Porter Novelli/Voce

Andrew Hussey

Andrew.hussey@porternovelli.com

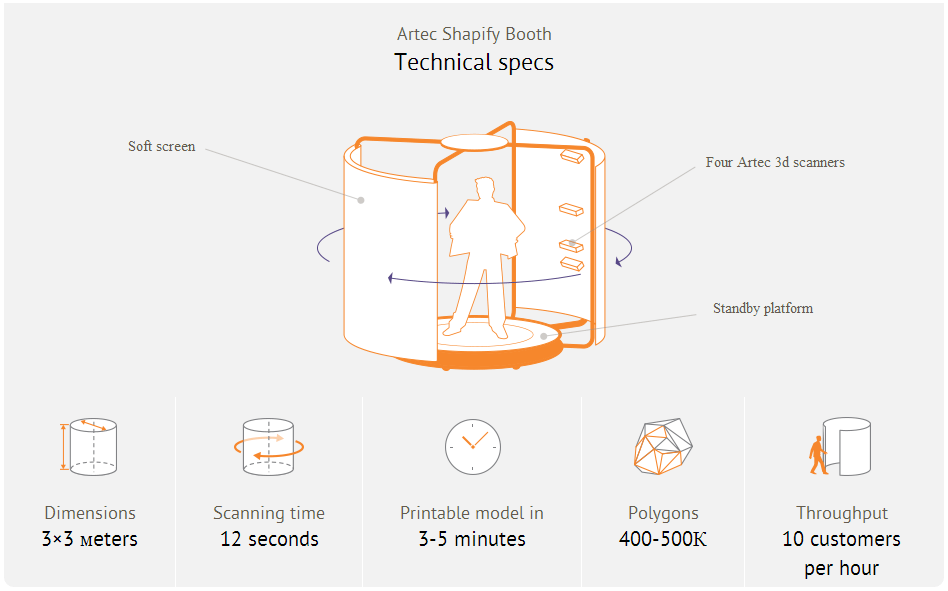

Artec Announces the World’s First 3D Full Body Scanner – Shapify Booth

/0 Comments/in 3D Laser Scanning, In the News, New Hardware, New Technology, News, Photogrammetry, Point Cloud/by Travis ReinkeA twelve second body scan and shoppers pick up their 3D printed figurine next time they visit the supermarket

P-3D SELFIE_ITV2000_Vimeo from Granada Reports on Vimeo.

This week Asda and Artec Group are happy to announce their partnership as Asda becomes the first supermarket to bring a new cutting edge 3D printing technology to shoppers in the UK with the installation of Artec Shapify Booth — the world’s first high speed 3D full body scanner in its Trafford Park store. The scanning booth will allow thousands of customers to create a 3D miniature replica of themselves.

The Artec scanning booth, equipped with wide-view, high-resolution 3D scanners and a rotation rig, takes just 12 seconds to scan a person. The Artec algorithms automatically fuse 700 captured surfaces into a detailed printable file. This digital model is then sent to the Asda 3D printing centre to be made into an 8″ mini-statue in full colour which can be collected from the store just one week later. Asda’s unique 3D printing technologies allows the processing of a huge volume of high quality figurines at a time, while the prints costs just £60.

Asda first introduced 3D scanning and 3D printing customer’s figurines six months ago, using Artec handheld scanners. Driven by the immediate success of the venture and Asda’s vision to offer 3D technology to the public, Artec Group tailored its professional scanning equipment to spec and created the Shapify Booth, a high speed full body scanner that Asda is now making available to all.

Making 3D prints of all the family, customers can also come along to be scanned in their sports kit, wedding outfits, graduation robes or fancy dress, taking something totally new and personalised back home with them after their weekly shop.

If the trial of the Shapify technology at Trafford Park is successful the new booths will be rolled out to more stores in the Autumn.

Phil Stout, Asda Innovation Manager – Asda is fast becoming, not just a retailer but, a technology company and this innovation is another example of how we’re leading the way on in store consumer facing technology. We’ve been working with Artec technology for a while now and we’re delighted to be the first company in the world able to offer our customers this unique service.

Artyom Yukhin, Artec Group President and CEO – Over the last 5 years Artec has been providing 3D technologies to professionals in industries from space and automotive to medical and movie special effects, but we have always been looking for the chance to do something for the public. Asda’s backing and second to none customer understanding allowed us to create high speed scanners which are fun and easy for people to use.

About Asda Stores Ltd.

Founded in the 1960s in Yorkshire, Asda is one of Britain’s leading retailers. It has more than 180,000 dedicated Asda colleagues serving customers from 551 stores, including 32 Supercentres, 311 Superstores, 29 Asda Living stores, 179 Supermarkets, 25 depots and seven recycling centres across the UK. Its main office is in Leeds, Yorkshire and its George clothing division is in Lutterworth, Leicestershire. More than 18 million people shop at Asda stores every week and 98 per cent of UK homes are served by www.asda.com. Asda joined Walmart, the world’s number one retailer, in 1999.

About Artec Group

Artec Group is a manufacturer and developer of professional 3D hardware and software, headquartered in Luxembourg. Artec Group is a global market leader in 3D scanning solutions used by thousands of people all over the world.

Shapify, the technology for creating 3D printed figurines, was conceived and launched by Artec Group in 2013:www.shapify.me

For more information about Artec Group, visit www.artec-group.com.

Contacts:

Artec Group : press@artec-group.com

Mantis Vision’s MV4D Tapped As Core 3D Capture Tech Behind Google’s Project Tango Tablets

/0 Comments/in 3D Laser Scanning, In the News, LiDAR, Mobile Scanning, New Hardware, New Technology, Point Cloud, Software, Visual Effects (VFX)/by Travis ReinkeMantis Vision, a developer of some of the world’s most advanced 3D enabling technologies, today confirmed that its MV4D technology platform will serve as the core 3D engine behind Google’s Project Tango. Mantis Vision provides the 3D sensing platform, consisting of flash projector hardware components and Mantis Vision’s core MV4D technology which includes structured light-based depth sensing algorithms.

“3D represents a major paradigm shift for mobile. We haven’t seen a change this significant since the introduction of the camera-phone. MV4D allows developers to deliver 3D-enabled mobile devices and capabilities to the world,” said Amihai Loven, CEO, Mantis Vision. “This partnership with Google offers Mantis Vision the flexibility to expand quickly and strategically. It will fuel adoption and engagement directly with consumer audiences worldwide. Together, we are bringing 3D to the masses.”

MV4D is Mantis Vision’s highly-scalable 3D capture and processing platform that allows developers to integrate Mantis’ technology into new and existing applications with ease, to drive user-generated 3D content creation throughout the mobile ecosystem. MV4D’s combination of field-proven 3D imaging hardware and software and a soon-to-be released software development kit (SDK) will ultimately serve as the backbone of 3D-enabled mobile and tablet devices.

“We are excited about working with partners, such as Mantis Vision, as we push forward the hardware and software technologies for 3D sensing and motion tracking on mobile devices,” said Johnny Lee, Technical Product Lead at Google.

Since its inception, Mantis Vision has been dedicated to bringing professional-grade 3D technology to the masses. The company’s technology will be a key component of both professional and consumer level devices and applications across a wide customer base of leading mobile technology companies, application developers and device manufacturers. Because the MV4D platform and SDK is fully scalable, it is already being planned for use in more powerful, diverse range of products in the future.

Microsoft Kinect for Windows v2: Affordable MoCap and 3D Scanning Solution

/0 Comments/in 3D Laser Scanning, New Hardware, New Technology, Point Cloud, Visual Effects (VFX)/by Travis ReinkeAmid the volley of announcements from Microsoft’s Build conference, is word that the new Kinect for Windows has a near-future release timeframe for both the hardware and its SDK. The desktop version of Microsoft’s do-all sensor will be available to the public this summer, as will its development framework. Perhaps more importantly, once they’re done, developers can publish their creations to the Windows Store; meaning, there’ll probably be more Kinect applications for Windows in one place than ever before. As Redmond tells it, this self-publishing will happen “later this summer.” Next summer, Microsoft is adding support for one of gaming’s most pervasive dev toolkits to Kinect for Windows: the Unity engine — tools developers already know the strengths and weaknesses of, which should bolster the app selection even further. Given that the Xbox One will see Unity support this year, this could mean that cross-platform apps and games are a distinct possibility.

With the specs of Kinect for Windows V2, the 3D scanning and imaging industries may be in for a game-changer. Indie film and game developers will hopefully be able to take advantage of its features as an affordable motion capture (mocap) solution.

Kinect motion capture guru and programmer, Jasper Brekelmans, has been playing with the second release of the Kinect for quite some time and has been posting some impressive results. You can stay on top of everything he is doing on his personal site http://www.brekel.com/.

You can pre-order your Kinect for Windows V2 today for $199 from the Microsoft Store.

Mobile Scanners Enter the Rental Market

/0 Comments/in LiDAR, Mobile Scanning, New Hardware/by Travis ReinkeThe Only Portable Mobile Mapping & GIS Data Collection Solution is now available for daily, weekly and monthly rental.

Measurement Devices Ltd. announces the world-wide availability of Dynascan equipment hire/rental giving even the smallest survey organizations the ability to add mobile mapping to its service offering, enabling them to undertake previously undreamed of ‘detailed 3D, large scale mapping projects’, formerly the domain of large companies or government organizations. Productivity of Laser Surveying Systems will no longer be measured in terms of “Points per Second” but in terms of “Square Miles per Hour” and available for the same cost-effective daily hire rate as static terrestrial 3D laser scanning systems (i.e. Leica Geosystems ScanStation C10, HDS6200, HDS7000).

Furthermore, MDL has assembled a global team of LiDAR industry experts to provide field and office support services and custom-tailored training on “real-world” workflows and procedures. Travis Reinke, Chief Operating Officer of Measurement Devices US, LLC stated, “By providing easy access to the latest technology and expertise, we are able to change the decision-making process. Project managers and the like now have the ability to integrate new technologies into their workflows without the huge risk of taking on large capital expenditures. We’re disrupting the market by introducing mobile mapping to the masses.”

MDL’s new business model of providing ‘complete measurement solutions’ gives greater support to customers with irregular or infrequent resource needs or project specific requirements. Reinke went on to add, “Our highly-skilled team of professionals are available to ensure that first-time users are successful on their first project. We accomplish this by offering a discounted bundled rate for an experienced technician and the mobile system when needed.”

MDL’s mission is:

- To assist and enable more end-users in the real-world application of various rapid 3D data capture technology by providing easy access to a comprehensive range of equipment rental, consultancy and education.

- To help end-users close the information gap between the Hardware/Software Vendors and the real world.

- To empower and educate our client base in order to enhance industry growth and spawn further advancements.

- To support customers with irregular or infrequent resource needs or project specific requirements.

With decades of combined experience gained from a real world application of laser measurement systems, MDL’s team of industry professionals has obtained a highly qualified and proven skill set focused on Quarry and Mining Surveying, Dynamic Land Surveying, High Definition Surveying, and Hydrographic Surveying.

Eliminate the Investment Risk

- Rent equipment until you’re ready to buy – expense on per project basis.

- Take advantage of knowledgeable experts with real world experience to support your project team.

- Ramp up or down as needed to keep your capital expenditures minimal.

- Rely upon our experience to provide you with practical user information and get more than just a demo.

The Dynascan ‘Plug and Play’ LIDAR system is a fully integrated high speed laser scanner, high accuracy GPS positioning system and Inertial Measurement Unit. The system is light weight, highly portable and may be used on land vehicles or marine vessels to acquire 3D survey quality data of topography, urban developments, industrial plants, including overhead utility cables, bridges, dams, harbors, beaches, rivers and canal banks, and much more.

By fully integrating all the sensors in one package, MDL has eliminated the need for field calibrations as all sensor offset measurements are fixed during the factory calibration process and pre-configured in the data acquisition software. The LIDAR system is shipped ready for operation and can be mobilized in a matter of minutes.

Dynascan system comes complete with data acquisition and post processing software suite which is compatible with all known brand multi-beam echo sounders, swathe sonar systems, positioning systems and Inertial Measurement Units. Data from all available sensors is synchronized, “Time Tagged” and Recorded. Post processed and raw data may be exported to most 3D data base and CAD software packages. Dynascan is highly affordable and represents an unrivalled ‘Price-Performance’ advantage, opening up the benefits of 3D LIDAR to numerous applications and market opportunities.

FARO Introduces the Focus3D – the Smallest and Lightest 3D Laser Scanner Ever Built

/0 Comments/in In the News, New Hardware, New Technology/by Travis Reinke

Focus3D is a revolutionary, high-performance 3D laser scanner for detailed measurement and documentation with intuitive touch screen control that makes it as easy to operate as a digital camera. It is four times lighter and five times smaller than its predecessor and is the smallest and lightest laser scanner ever built.

Focus3D uses laser technology to produce incredibly detailed three-dimensional images of complex environments and geometries in only a few minutes. The resulting image is an assembly of millions of 3D measurement points in color which provides an exact digital reproduction of existing conditions.

The new FARO Laser Scanner Focus3D is suitable for documentation of large environments, quality control of components and reverse engineering. Thanks to its millimeter-accuracy and its 976,000 measurement points/second, the Focus3D offers the most efficient and precise method for measurement and three-dimensional documentation of building construction, excavation volumes, façade and structural deformations, crime scenes, accident sites, product geometry, factories, process plants and more.

The Focus3D is entirely self-contained, meaning no additional devices, cables or laptop are needed. With its dimensions of 9.5 x 8 x 4 in. and a weight of 11lbs, the Focus3D is so compact and mobile that users can always take it with them, wherever they go.

Focus3D deploys an integrated color camera with automatic and parallax free color overlay for photo-realistic 3D scans. Its integrated lithium-ion high-performance battery provides up to five hours of battery life and can be charged during operation. Furthermore, all scans are stored on a SD card enabling easy and secure data transfer to a computer.

The FARO Focus3D is compatible with many common software applications. The flexible interfaces of SCENE, the scan processing software included with the Focus3D, enable connection to AutoCAD as well as many other CAD applications such as Rhino, Microstation, Nemetschek and ArchiCAD.

FARO has changed the game with all the improvements and features of the new Focus3D, eclipsing anything offered in the marketplace and reducing the package size by 50%. Instead of pricing the technology accordingly, FARO has dropped the price by half that of any current laser scanning system.

“With the revolutionary Focus3D, FARO provides architects, civil engineers and plant designers with an efficient tool for rapid, seamless and precise documentation of the current status of buildings, plants and construction sites of every kind. The Focus3D offers advanced functionality through a simple user interface and expands the user base beyond the expert, moving phase shift laser scanning across the technology chasm,” stated Jay Freeland, FARO’s Chief Executive Officer.

About FARO

FARO develops and markets computer-aided coordinate measurement devices and software. Portable equipment from FARO permits high-precision 3D measurement and comparison of parts and compound structures within production and quality assurance processes. The devices are used for inspecting components and assemblies, production planning, inventory documentation, as well as for investigation and reconstruction of accident sites or crime scenes. They are also employed to generate digital scans of historic sites.

Worldwide, approximately 10,000 customers are operating more than 20,000 installations of FARO’s systems. The company’s global headquarters is located in Lake Mary, Florida, with its European head office in Stuttgart, Germany and its Asia/Pacifichead office in Singapore. FARO has branch locations in Canada, Mexico, United Kingdom, France, Spain, Italy, Poland, Netherlands, India, China, Singapore, Malaysia, Vietnam, Thailand, and Japan.

SOURCE FARO Technologies, Inc.

RELATED LINKS

http://www.faro.com

Quick Pages

Recent Productions

Latest News

- A $1.5B Investment in Texas’ Film is Now LawJune 23, 2025 - 4:49 pm

- Daredevil: Born Again: the art and craft of critical VFX collaborationMay 3, 2025 - 1:58 pm

- Here are all the nominees for the 23rd Annual VES AwardsJanuary 15, 2025 - 6:58 pm