Here are all the nominees for the 23rd Annual VES Awards

/0 Comments/in Blog, Featured, LiDAR, Mobile Scanning, Modeling, Photogrammetry, Uncategorized, Visual Effects (VFX)/by Ty TaylorSCANable Strengthens Existing West Coast Presence

/0 Comments/in Blog, Featured, LiDAR, Mobile Scanning, Modeling, Photogrammetry, Uncategorized, Visual Effects (VFX)/by Ty TaylorMoPho Studios announced by the leading VFX 3D Scanning Studio – SCANable

/0 Comments/in Blog, Featured, LiDAR, Mobile Scanning, Modeling, Photogrammetry, Uncategorized, Visual Effects (VFX)/by Ty TaylorPIXAR Deep Dive on SSS: SIGGRAPH Preview

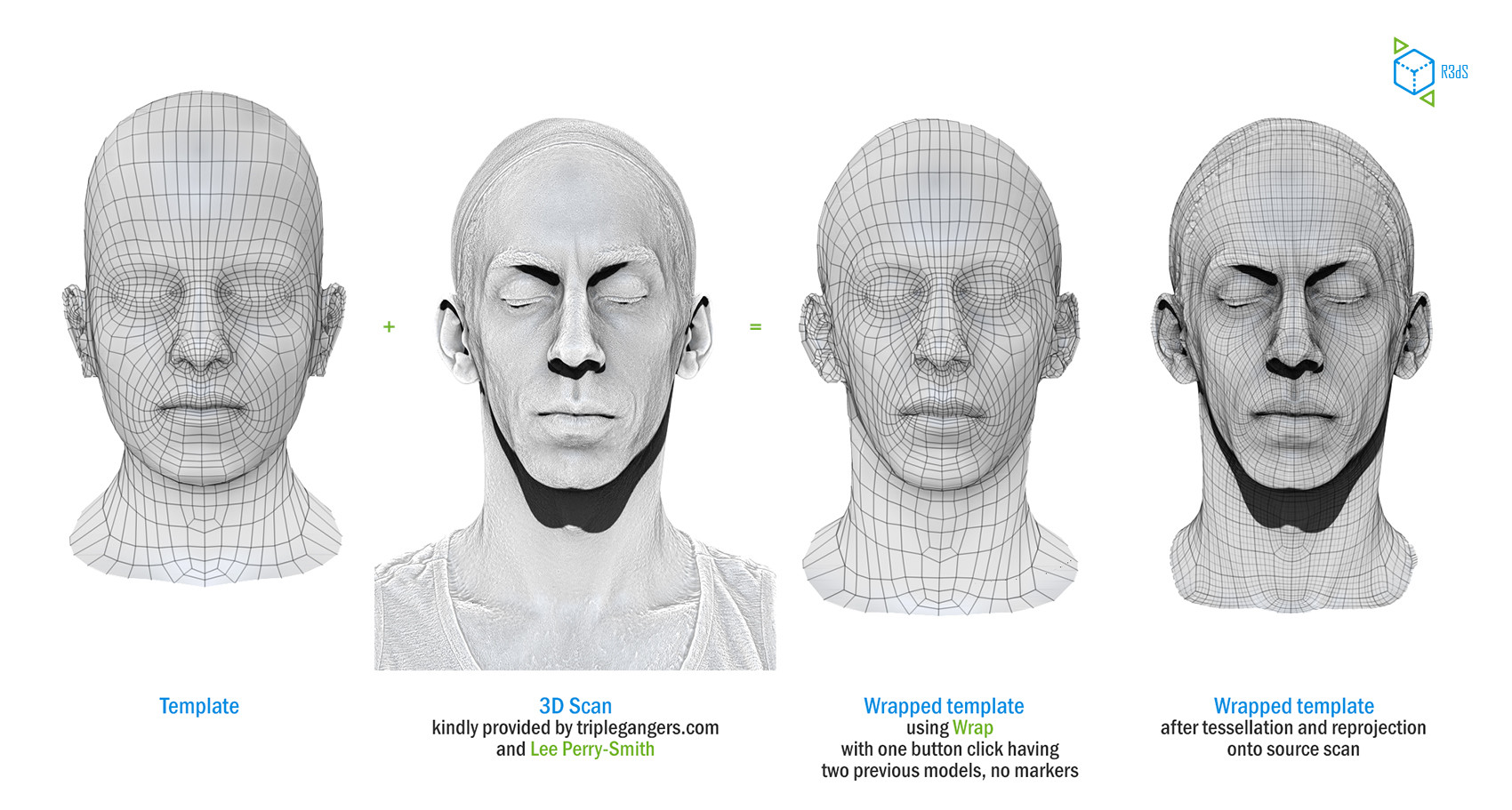

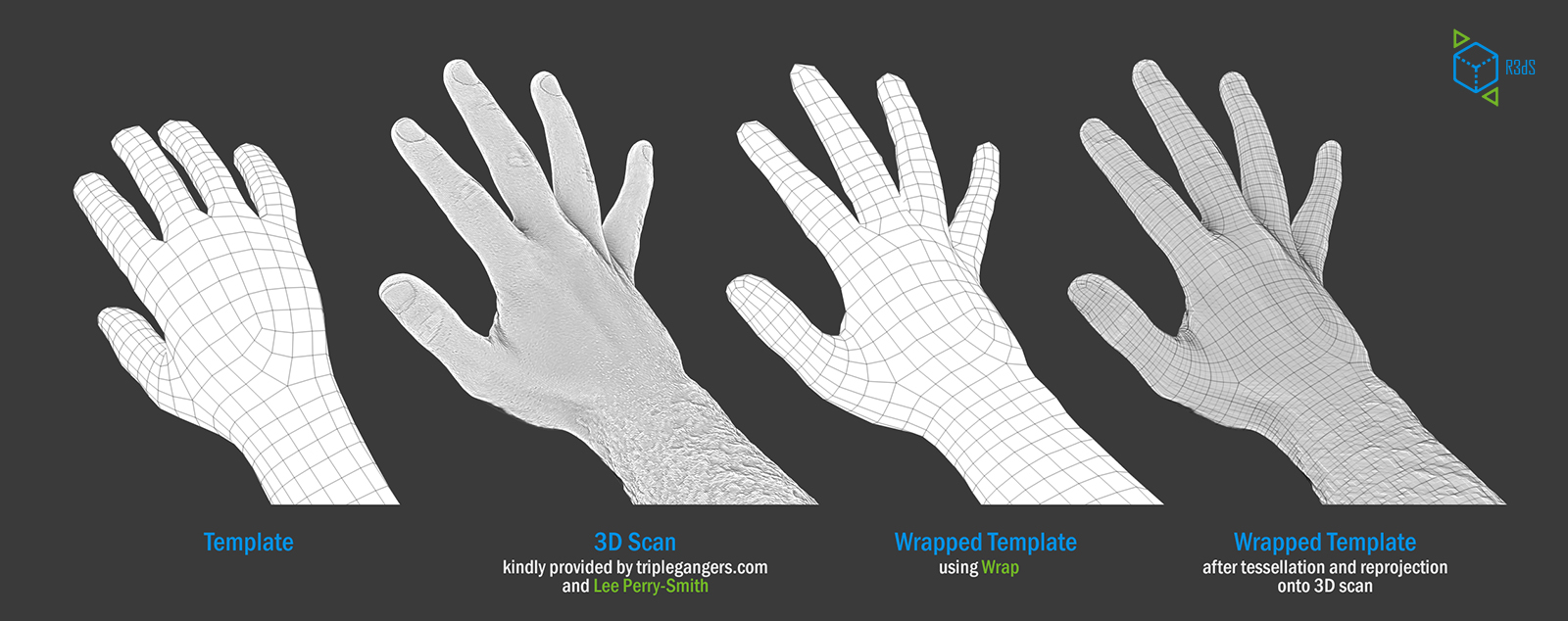

/in 3D Laser Scanning, Blog, In the News, Modeling, New Technology, Virtual Reality, Visual Effects (VFX)/by Ty TaylorIntroducing R3DS Wrap – Topology Transfer Tool

/0 Comments/in Modeling, New Technology, Software, Visual Effects (VFX)/by Travis ReinkeWrap is a topology transfer tool. It allows to utilize the topology you already have and transfer your new 3D-scanned data onto it. The resulting models will not only share the same topology and UV-coordinates but also will naturally become blendshapes of each other. Here’s a short video how it works:

and here are a couple of examples based on 3D-scans kindly provided by Lee Perry-Smith

You can download a demo-version from their website http://www.russian3dscanner.com

As with all new technology during its final beta stages, Wrap is not perfect yet. R3DS would be highly appreciative and grateful of everyone that gives us the support and feedback to finalize things in the best possible way. This software has some potential to be a great tool. Check it out!

Autodesk Aims to Streamline Use of Point Cloud Data

/0 Comments/in 3D Laser Scanning, In the News, Modeling, Photogrammetry, Point Cloud, Software/by Travis ReinkeA key addition to the complete 2014 portfolio of Suites is Autodesk® ReCap™ product, a family of powerful and easy-to-use software and services on the desktop and in the cloud to create intelligent 3D data from captured photos and laser scans in a streamlined workflow. Autodesk ReCap is the first industry solution to bring together laser scanning and photogrammetry into one streamlined process. In addition, no other solution on the market provides the visualization quality and scalability to handle extremely large data sets.

The Autodesk ReCap product line comprises two main offerings – Autodesk ReCap Studio and Autodesk ReCap Photo. Autodesk ReCap Studio makes it easy to clean, organize and visualize massive datasets captured from reality. Autodesk ReCap Photo helps users create high-resolution textured 3D models from photos using the power of cloud computing. Rather than beginning with a blank screen, Autodesk ReCap now enables any designer, architect or engineer to add, modify, validate and document their design process in context from existing environments.

For example, a civil engineer can bypass an existing bridge or expand the road underneath digitally and test feasibility. At construction phase, builders can run clash detection to understand if utilities will be in the way. Urban planners can get answers to specific design questions about large areas, such as how much building roof surface is covered by shadow or vegetation.

ReCap Studio is a data preparation environment that runs on the desktop. Users can import captured data directly into Autodesk design solutions, such as AutoCAD®, Autodesk® Revit®, Autodesk Inventor®, etc., to conduct QA and verification of data. The data can come from non-intelligent, black and white sparse point clouds to intelligent, visually high appealing content. ReCap Studio will ship in Autodesk product and suite installers or be available for free on the Autodesk Exchange Apps store.

ReCap Photo is an Autodesk 360 service designed to create high resolution 3D data from photos to enable users to visualize and share 3D data. By leveraging the power of the cloud to process and store massive data files, users can upload images on Autodesk 360 and instantly create a 3D mesh model. ReCap Photo is available with Standard Suites entitlement and higher.

Key features of Autodesk ReCap include:

- Visualize and edit massive datasets: On the desktop, ReCap users can view and edit billions of points to prepare them for use in Autodesk portfolio products to enable realistic in context design work

- Professional-Grade Photo to 3D Features: ReCap unlocks the power of ubiquitous cameras to capture high-quality 3D models, bringing reality capture within reach of anyone with a camera. ReCap supports objects of any size and range, full resolution for high-density meshes, survey points and multiple file exports.

- Photo and Laser: ReCap incorporates the best of both photo and laser data capture so that customers can use photos to fill in holes or augment laser scan data. Users can both increase photos scene accuracy with laser points and add photo-realistic detail to laser scans. Create point clouds from photos, align scans and photos and convert professional grade photo to 3D models.

Autodesk continues to invest in developing sophisticated, easy-to-use reality capture technologies. The company has made several key acquisitions including Alice Labs and Allpoint Systems as well as applied its own research and development resources to accelerate the mainstream adoption of these technologies. As customers are looking for ways to easily and accurately capture the world around them, Autodesk ReCap streamlines Reality Capture workflows, making working with Reality Capture data easy, quick and cost effective.

Autodesk is the only company who has combined laser scanning data and photogrammetry into one product family to address and streamline the entire workflow. Whereas traditional point clouds appear as dots, Autodesk technology can now visualize truly massive point clouds as realistic surfaces. Unique to Autodesk is that users can interact with these huge data sets doing CAD-like operations such as selection, tagging, moving, measuring, clash detection, and object extraction, all with native points. Laser scanning and photogrammetry are historically very expensive and data intensive. Autodesk’s goal is to democratize the process of reality capture so that anyone can capture the world around them to create high quality 3D models.

Leica Geosystems Announces Major Advances in Cyclone 8.0 Software

/0 Comments/in Modeling, Point Cloud, Software/by Travis ReinkeLeica Geosystems Announces Cyclone 8.0 Software – Major Advances for “Point Cloud” Office Productivity, Spatial Data Connectivity, and Customization

(Heerbrugg/Switzerland and Hanover/Germany, 9 October 2012) – Leica Geosystems announces the next major release of its flagship software, Leica Cyclone 8.0. In addition to providing further improvements in office productivity for processing as-built laser scan data, Cyclone 8.0 gives users powerful, new capabilities. Users can now directly connect point cloud data with other spatial data sources (such as 3D models) and readily share and re-use modeled data. Leica Cyclone 8.0 is being introduced at Intergeo as supporting software for the new Leica ScanStation P20 ultra-high speed laser scanner.

Office Productivity Gains

Cyclone 8.0 features several enhancements that increase office productivity, often significantly:

[listdot]

- 20 – 50% faster scan data import

- Automatic conversion on import to Enhanced Working Format, for faster data processing

- Automatic creation of all pipe cylinders, with a single click, for an entire project or for a selected set of scan data, even during import

- Automatic creation of TruView Hotlinks, linking scan points in panoramic TruViews to asset information

- Easy saving and re-use of complex models created from geometric primitives

- New “scripting” capability speeds repetitive or customized sequences of model building

- Fewer clicks and a modern CAD-like interface for popular “Move” and “Rotate” commands[/listdot]

ClearEdge3D Releases EdgeWise Plant™ 4.0

/0 Comments/in Modeling, Software/by Travis Reinke

Now offers full, end-to-end 3D modeling solution with 9 new features and enhancements including valve/flange placement, demolition tool, custom spec editor, high-definition visualization and more

Herndon, Virginia — December 12, 2012 — ClearEdge3D today released EdgeWise Plant™ 4.0, with 9 major new features and enhancements that create the fastest end-to-end pipe modeling solution on the market. The software automates the 3D modeling of complex process plant facilities, cutting up to 85% of labor from the modeling workflow.

Robert Greenhalgh with Ramboll Oil & Gas used the software on a recent North Sea offshore project. “We reduced our 3D modeling time substantially with EdgeWise Plant 4.0,” said Greenhalgh. ”Building standard pipe fittings on top of the powerful automated tools makes 4.0 the complete pipe modeling package.”

ClearEdge3D Launches EdgeWise MEP for Autodesk Revit

/0 Comments/in Modeling, Point Cloud, Software/by Travis Reinke

Automated Feature Extraction of pipes from point clouds now available for Revit—promises substantial workflow savings of up to 85%

Herndon, Virginia — September 5, 2012 — ClearEdge3D announced today the release of its latest product, EdgeWise MEP™ for Autodesk® Revit®. For the first time, users can bring extracted pipes, conduit and other cylindrical mechanical, electrical, and plumbing (MEP) elements directly into Revit. ClearEdge3D’s new MEP solution leverages the powerful feature extraction technology of EdgeWise to automatically extract pipe solids from laser scan point clouds. These pipe solids can be automatically connected into pipe runs, annotated within EdgeWise MEP, and then brought directly into Revit as fully functional Revit pipe objects. All intelligence extracted by EdgeWise, such as diameter, length, elbow bend radius and more, is also transferred into Revit.

Beta testers of EdgeWise MEP for Revit reported modeling time savings of up to 85 percent over their previous workflows. “EdgeWise MEP for Revit greatly enhances the field-to-finish workflow. It’s the innovation our BIM customers have been asking for,” said Chris Scotton, ClearEdge3D’s President and CEO. “Now users can combine the speed of EdgeWise Automated Feature Extraction with the power of Revit to produce Revit deliverables much faster than ever before.”

To request a live demonstration of EdgeWise MEP for Revit click here: www.clearedge3d.com.

About ClearEdge3D

ClearEdge3D was founded in 2006 by two recognized experts and thought-leaders in the field of computer vision, Automated Feature Extraction, and LIDAR data analysis. The company’s flagship products, EdgeWise Plant™, EdgeWise MEP™ for Revit and EdgeWise Building™, are used by top engineering firms world-wide to optimize their scan-to-model workflow. The company is privately-held and headquartered in Herndon, Virginia.

Autodesk and Revit are registered trademarks or trademarks of Autodesk, Inc., in the USA and other countries.

-###-

For more information, contact:

Janice Starrs

USA +1 410-991-0582

Quick Pages

Recent Productions

Latest News

- Daredevil: Born Again: the art and craft of critical VFX collaborationMay 3, 2025 - 1:58 pm

- Here are all the nominees for the 23rd Annual VES AwardsJanuary 15, 2025 - 6:58 pm

- SCANable Strengthens Existing West Coast PresenceDecember 21, 2024 - 6:34 pm