Boeing Launches Compact 3-D Imaging Camera

ALBUQUERQUE, N.M., March 8, 2010 — The Boeing Company [NYSE: BA] today announced it has begun offering a new, compact, energy-efficient camera that provides three-dimensional images for military and commercial applications.

ALBUQUERQUE, N.M., March 8, 2010 — The Boeing Company [NYSE: BA] today announced it has begun offering a new, compact, energy-efficient camera that provides three-dimensional images for military and commercial applications.

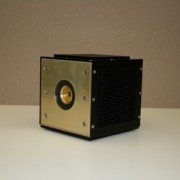

Boeing Directed Energy Systems and wholly owned Boeing subsidiary Spectrolab have jointly developed the camera using their own research and development funding, and successfully tested it over the past two years by attaching it to mobile ground platforms and a Boeing AH-6 Little Bird helicopter. Equipped with advanced sensors that were developed by the Massachusetts Institute of Technology’s Lincoln Laboratory and transferred to Boeing under a teaming arrangement, the cube-shaped camera is one-third the size and uses one-tenth the power of most comparable 3-D imaging cameras.

“Our three-dimensional camera fits a lot of capability into a small package,” said Nasser Karam, vice president of Advanced Technology Products at Spectrolab. “Its compact design and modest power needs will allow it to be deployed on a wide range of platforms, including unmanned aerial and ground vehicles that don’t have much room or power to spare.”

The camera, which Boeing can customize for each customer, has many potential uses, including mapping terrain, tracking targets and seeing through foliage. To create a 3-D image, the camera fires a short pulse of laser light, then measures the pulse’s flight time to determine how far away each part of the camera’s field of view is.

“The camera combines cutting-edge sensor technology with Boeing’s advanced pointing and tracking solutions and real-time processing to provide our customers with highly integrated 3-D imaging payloads for ground, airborne or space-based applications,” said Joseph Paranto, Growth lead for Directed Energy Systems in Albuquerque.

Boeing is currently integrating the camera into compact 3-D imaging payloads on unmanned aerial vehicles and will be testing that capability this spring. The team will also add 3-D video capability to the camera soon to complement its existing still-image capability.

A unit of The Boeing Company, Boeing Defense, Space & Security is one of the world’s largest defense, space and security businesses specializing in innovative and capabilities-driven customer solutions, and the world’s largest and most versatile manufacturer of military aircraft. Headquartered in St. Louis, Boeing Defense, Space & Security is a $34 billion business with 68,000 employees worldwide.

Source: http://boeing.mediaroom.com/index.php?s=43&item=1107

3D Laser Scanner Combines Phase and Time of Flight Technologies for Fast and Accurate Data Capture

3D Laser Scanner Combines Phase and Time of Flight Technologies for Fast and Accurate Data Capture The Trimble CX solution is built for efficient data capture in the plant. With reliable scanning at 50,000 points per second and an 80 meter range with a 360 degree x 300 degree field of view, the solution provides widespread and efficient data capture from a single setup. A rugged design, IP54 rating and protective housing for the rotating laser allow the scanner to deliver continuous and reliable results even in difficult industrial environments. An integrated camera collects additional image information that can improve the visualization, post-processing and communication of the captured data.

The Trimble CX solution is built for efficient data capture in the plant. With reliable scanning at 50,000 points per second and an 80 meter range with a 360 degree x 300 degree field of view, the solution provides widespread and efficient data capture from a single setup. A rugged design, IP54 rating and protective housing for the rotating laser allow the scanner to deliver continuous and reliable results even in difficult industrial environments. An integrated camera collects additional image information that can improve the visualization, post-processing and communication of the captured data. Nottingham, UK – 3D Laser Mapping has announced the UK launch of the world’s fastest and lightest mobile laser scanner. Designed to instantly 3D map buildings, infrastructure and highways to 5mm accuracy within half a kilometre, the Riegl VZ-400 represents a new generation of laser scanner technology. Weighing just 10kg and carried in a handy rugged briefcase, the added portability, accuracy and speed is set to revolutionise 3D field mapping.

Nottingham, UK – 3D Laser Mapping has announced the UK launch of the world’s fastest and lightest mobile laser scanner. Designed to instantly 3D map buildings, infrastructure and highways to 5mm accuracy within half a kilometre, the Riegl VZ-400 represents a new generation of laser scanner technology. Weighing just 10kg and carried in a handy rugged briefcase, the added portability, accuracy and speed is set to revolutionise 3D field mapping.