A key addition to the complete 2014 portfolio of Suites is Autodesk® ReCap™ product, a family of powerful and easy-to-use software and services on the desktop and in the cloud to create intelligent 3D data from captured photos and laser scans in a streamlined workflow. Autodesk ReCap is the first industry solution to bring together laser scanning and photogrammetry into one streamlined process. In addition, no other solution on the market provides the visualization quality and scalability to handle extremely large data sets.

The Autodesk ReCap product line comprises two main offerings – Autodesk ReCap Studio and Autodesk ReCap Photo. Autodesk ReCap Studio makes it easy to clean, organize and visualize massive datasets captured from reality. Autodesk ReCap Photo helps users create high-resolution textured 3D models from photos using the power of cloud computing. Rather than beginning with a blank screen, Autodesk ReCap now enables any designer, architect or engineer to add, modify, validate and document their design process in context from existing environments.

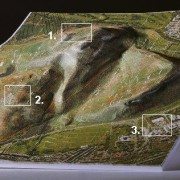

For example, a civil engineer can bypass an existing bridge or expand the road underneath digitally and test feasibility. At construction phase, builders can run clash detection to understand if utilities will be in the way. Urban planners can get answers to specific design questions about large areas, such as how much building roof surface is covered by shadow or vegetation.

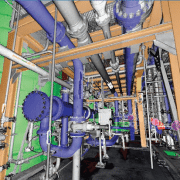

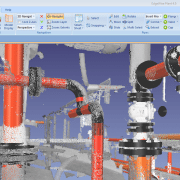

ReCap Studio is a data preparation environment that runs on the desktop. Users can import captured data directly into Autodesk design solutions, such as AutoCAD®, Autodesk® Revit®, Autodesk Inventor®, etc., to conduct QA and verification of data. The data can come from non-intelligent, black and white sparse point clouds to intelligent, visually high appealing content. ReCap Studio will ship in Autodesk product and suite installers or be available for free on the Autodesk Exchange Apps store.

ReCap Photo is an Autodesk 360 service designed to create high resolution 3D data from photos to enable users to visualize and share 3D data. By leveraging the power of the cloud to process and store massive data files, users can upload images on Autodesk 360 and instantly create a 3D mesh model. ReCap Photo is available with Standard Suites entitlement and higher.

Key features of Autodesk ReCap include:

- Visualize and edit massive datasets: On the desktop, ReCap users can view and edit billions of points to prepare them for use in Autodesk portfolio products to enable realistic in context design work

- Professional-Grade Photo to 3D Features: ReCap unlocks the power of ubiquitous cameras to capture high-quality 3D models, bringing reality capture within reach of anyone with a camera. ReCap supports objects of any size and range, full resolution for high-density meshes, survey points and multiple file exports.

- Photo and Laser: ReCap incorporates the best of both photo and laser data capture so that customers can use photos to fill in holes or augment laser scan data. Users can both increase photos scene accuracy with laser points and add photo-realistic detail to laser scans. Create point clouds from photos, align scans and photos and convert professional grade photo to 3D models.

Autodesk continues to invest in developing sophisticated, easy-to-use reality capture technologies. The company has made several key acquisitions including Alice Labs and Allpoint Systems as well as applied its own research and development resources to accelerate the mainstream adoption of these technologies. As customers are looking for ways to easily and accurately capture the world around them, Autodesk ReCap streamlines Reality Capture workflows, making working with Reality Capture data easy, quick and cost effective.

Autodesk is the only company who has combined laser scanning data and photogrammetry into one product family to address and streamline the entire workflow. Whereas traditional point clouds appear as dots, Autodesk technology can now visualize truly massive point clouds as realistic surfaces. Unique to Autodesk is that users can interact with these huge data sets doing CAD-like operations such as selection, tagging, moving, measuring, clash detection, and object extraction, all with native points. Laser scanning and photogrammetry are historically very expensive and data intensive. Autodesk’s goal is to democratize the process of reality capture so that anyone can capture the world around them to create high quality 3D models.

Open on the input

Open on the input

FRANKFURT, Germany, November 29, 2012 /PRNewswire/ —

FRANKFURT, Germany, November 29, 2012 /PRNewswire/ —

Stockholm, Sweden, 12 November 2012

Stockholm, Sweden, 12 November 2012