INOVx Announces Release of RealityLINx 5.4 and Leica HDS pcE Support

A New Milestone in the Leica Geosystems HDS / INOVx Partnership

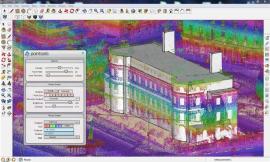

This latest release of RealityLINx, also breaks ground as the first offering from a partnership with Leica Geosystems HDS to jointly develop and distribute advanced software for converting laser scan data into intelligent plant models. Through this partnership with Leica Geosystems, the RealityLINx platform now incorporates the powerful point cloud engine (pcE) from Leica Cyclone. This combination of Leica and INOVx technologies found in RealityLINx 5.4 enables the transformation of laser scans of as-built assets into highly accurate geometries and intelligent asset models, faster than ever before possible. The Leica Geosystems / INOVx collaboration is grounded in an open solutions approach that can be deployed regardless of the specific type of laser scanner used or plant design software involved. The RealityLINx family of CAD adapters has also been expanded to support the import and synchronization of Leica Cyclone (COE) models into RealityLINx intelligent asset models.

Customers that rely on RealityLINx for creating plant models from laser scans will realize a number of benefits with the 5.4 release, including:

- enhancements in assisted, rapid modeling of steel structural elements

- display scan points for >10x as many scanner positions

- speed up display times by >25x for regions of point clouds that include multiple scanner positions

- quickly “clip” or remove undesired scan points near objects of interest, even with >40 regions displayed

- eliminate time consuming scan data format conversion and import/export steps

- display true color point clouds that look exactly like the real plant object

Finally, this release of RealityLINx also marks an expanded business agreement between Leica Geosystems and INOVx, establishing Leica Geosystems HDS the sole distribution channel for the RealityLINx Model product. Leica Geosystems will also offer, via their global distribution channels, the RealityLINx View and RealityLINx Manage products.

Industry Embracing the Benefits of Plant Models from Laser Scans

The use of 3D laser scanning to capture as-built geometry of plants has grown rapidly. This technology is driving improvements in the accuracy and completeness of Asset Documentation, providing customers with a foundation for better safety and environmental compliance. In addition, industry is increasingly taking advantage of intelligent 3D models developed from laser scans of facilities in order to drive new efficiencies in work processes ranging from design and construction through operations and maintenance. This new Asset Virtualization approach is transforming the way plant assets are managed, across the industry. By enabling the rapid construction of highly accurate models from laser scans, the RealityLINx platform accelerates activities in both Asset Documentation and Asset Virtualization solutions.

“We are pleased to already be delivering on the partnership we announced earlier this year with Leica Geosystems. Over the coming months and years, our combined technologies and efforts in providing tools for the rapid modeling of plant assets will set the standard for the process industries and benefit customers of both Leica and INOVx. Improvements in the creation of intelligent models from laser scans of as-built facilities further accelerates deployment of INOVx’s Asset Virtualization solutions by making these solutions faster, more cost effective, more functional and easier to maintain,” says Costantino Lanza, CEO of INOVx.

“Leica Geosystems is very excited to take this next, important step with INOVx. The new product, RealityLINx 5.4, is not only a great example of the significant productivity advantages of Leica point cloud Engine (pcE) technology in third party point cloud software, but our expanded partnership also provides customers with an even more complete laser scanning product solution offering from Leica Geosystems for the plant market,“ states Juergen Dold, CEO, Leica Geosystems.

About INOVx

INOVx, founded in 1999, provides a platform and solutions for Asset Virtualization® to companies in the process industries worldwide. INOVx’s RealityLINx product enables the creation, management and access to high fidelity three dimensional views of plant assets. These views are used in daily work practices to better communicate and navigate all asset information. INOVx solutions support many plant functions such as reliability, safety, operations, maintenance, inspection, and engineering. INOVx is a pioneer and thought leader in the application of laser scanning technology for the creation of accurate and precise three dimensional models of existing facilities. This Asset Documentation Service offers a reliable and proven way of creating and maintaining the three dimension asset models. INOVx is headquartered in Irvine, California. For more information please visit www.inovx.com..

Leica Geosystems – when it has to be right

With close to 200 years of pioneering solutions to measure the world, Leica Geosystems products and services are trusted by professionals worldwide to help them capture, analyze, and present spatial information. Leica Geosystems is best known for its broad array of products that capture accurately, model quickly, analyze easily, and visualize and present spatial information.

Those who use Leica Geosystems products every day trust them for their dependability, the value they deliver, and the superior customer support. Based in Heerbrugg, Switzerland, Leica Geosystems is a global company with tens of thousands of customers supported by more than 3’500 employees in 28 countries and hundreds of partners located in more than 120 countries around the world. Leica Geosystems is part of the Hexagon Group, Sweden.

PITTSBURGH, PA — (Marketwire) — 10/29/09 — Quantapoint (

PITTSBURGH, PA — (Marketwire) — 10/29/09 — Quantapoint ( Direct Integration: Integrate laser data with Revit directly, without sub-sampling or converting to “polygon meshes.”

Direct Integration: Integrate laser data with Revit directly, without sub-sampling or converting to “polygon meshes.” On Sepember 1, 2009, Leica Geosystems and Point of Beginning Magazine hosted a webinar titled The Business of Laser Scanning — hype or competitive advantage? Presenters Michael Harvey and

On Sepember 1, 2009, Leica Geosystems and Point of Beginning Magazine hosted a webinar titled The Business of Laser Scanning — hype or competitive advantage? Presenters Michael Harvey and  Some of the benefits of the new

Some of the benefits of the new  Company: ClearEdge3D

Company: ClearEdge3D Ease of Use:

Ease of Use: Our industry never comes short in the innovation department.

Our industry never comes short in the innovation department.