ClearEdge3D Releases EdgeWise Plant™ 4.0

Now offers full, end-to-end 3D modeling solution with 9 new features and enhancements including valve/flange placement, demolition tool, custom spec editor, high-definition visualization and more

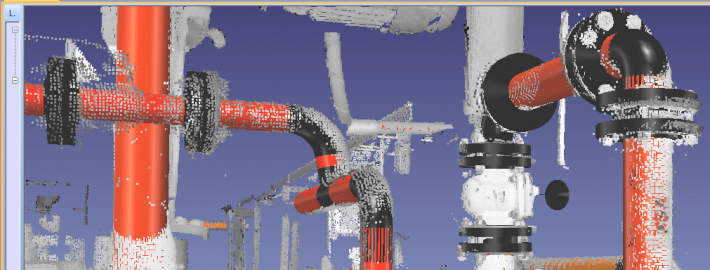

Herndon, Virginia — December 12, 2012 — ClearEdge3D today released EdgeWise Plant™ 4.0, with 9 major new features and enhancements that create the fastest end-to-end pipe modeling solution on the market. The software automates the 3D modeling of complex process plant facilities, cutting up to 85% of labor from the modeling workflow.

Robert Greenhalgh with Ramboll Oil & Gas used the software on a recent North Sea offshore project. “We reduced our 3D modeling time substantially with EdgeWise Plant 4.0,” said Greenhalgh. ”Building standard pipe fittings on top of the powerful automated tools makes 4.0 the complete pipe modeling package.”

The new features and enhancements in EdgeWise Plant 4.0 are a major step forward in pipe modeling technology. They include:

[listdot]

- Better automated pipe extraction algorithms automatically model up to 90% of the pipes in a project

- Dimensionally-accurate component placement from 4.0’s extensive new specification-driven component library (see a video of how component placement works by clicking here or go to http://www.clearedge3d.com/Products.aspx?show=EdgeWisePlantNewFeatures )

- Demolition tool easily removes pipes and associated points from the point cloud

- Custom specification editor can import or create new specifications

- Billion-plus point cloud visualization engine gives a high-definition view of the project

- Fast end-to-end pipe editing tools get you from field-to-finish in record time

[/listdot]

“The new tools in EdgeWise Plant 4.0 make the software a true field-to-finish pipe modeling package,” said Chris Scotton, ClearEdge3D’s President & CEO. “The improved extraction algorithms along with the component catalog, custom spec editor and extensive finishing tools redefine the man-hours required to model complex pipe geometry.”

“This is by far our most ambitious software release ever,” commented Kevin Williams, ClearEdge3D’s founder and Chief Scientist. “The speed it delivers to the modeling workflow can change the economics of 3D modeling. Customers are reporting savings of up to 85% over traditional modeling methods.” Larry Kleinkemper, President of Lanmar Service, an early user of the software, shares that assessment. “To be honest, I can’t imagine why a firm with a pipe modeling project wouldn’t use EdgeWise Plant 4.0.” Ramboll’s Greenhalgh agrees. “4.0 should be in every pipe modeler’s toolbox.”

To evaluate EdgeWise Plant 4.0 for your modeling toolbox, contact Janice Starrs at janice.starrs@clearedge3d.com or click here to watch a video of the software’s new features: www.clearedge3d.com.

About ClearEdge3D

ClearEdge3D was founded in 2006 by recognized experts and thought-leaders in the field of computer vision, Automated Feature Extraction, and LIDAR data analysis. The company’s flagship products EdgeWise Plant™ and EdgeWise MEP™ for Revit are used by top engineering firms worldwide to optimize their scan-to-model workflow. The company is privately-held and headquartered in Herndon, Virginia.

-###-

For more information, contact:

Janice Starrs

USA +1 410-991-0582

Leave a Reply

Want to join the discussion?Feel free to contribute!